Gallery Of Homes: Hastings

Kurt operates a vibratory screed to create a uniform consolidation of the aggregate in the concrete.

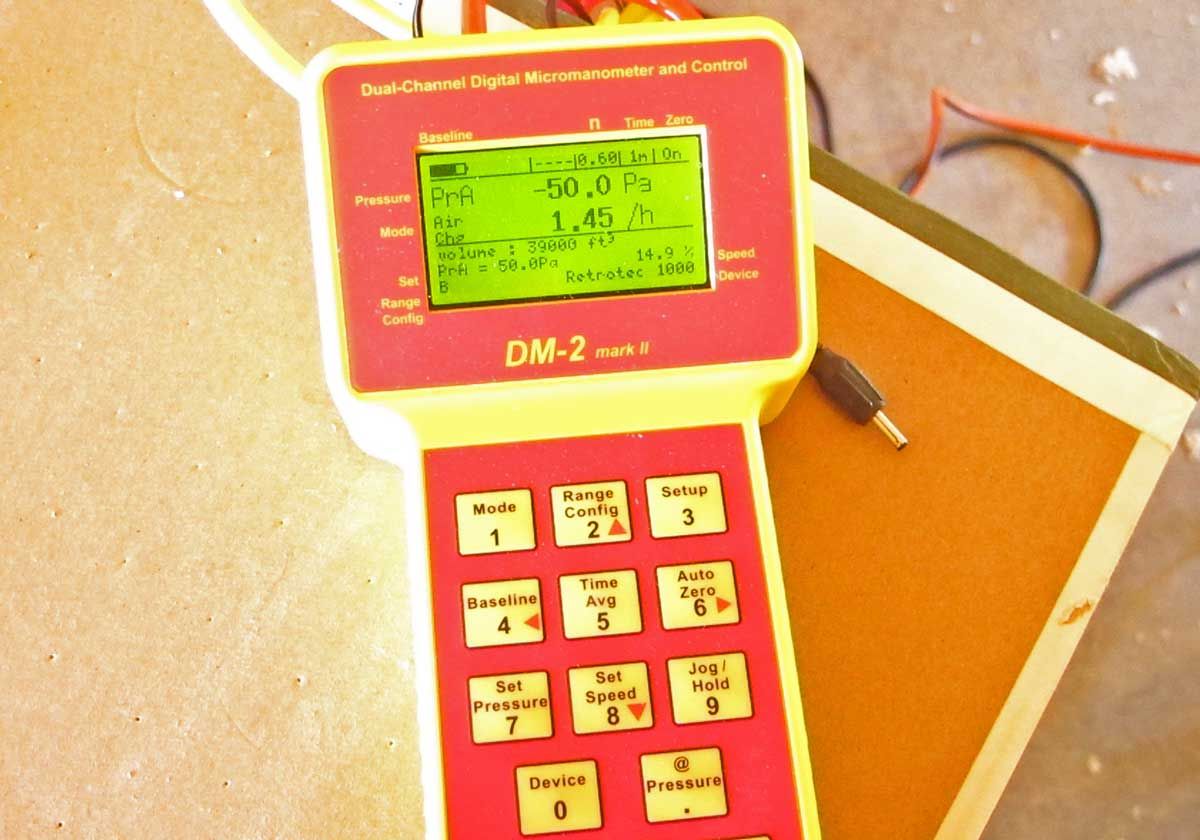

We use our door fan to measure air leakage at the framing stage and again at completion. It's not enough just to do all the right things and hope for the best. It's critical to test for success and find all the areas that were missed and seal them up. We don't just say we build a high performance energy efficient home, we prove it!

The door

fan draws a 50 pascal vacuum on the building which simulates a 20 mph

wind on all 4 sides and top of the home and measures the number of air changes

per hour leaking into the home (ACH50).

We tested 1.45 ACH at the framing stage which would classify as Super High Performance Home

These are the national performance guidelines:

1.5 - 4 ACH = High Performance Home

4 - 7 ACH = Energy Efficient Home

8 - 12ACH = Standard New Home

11 - 21ACH = Standard Existing Home

18 - 35ACH = Standard Older Home

Here's the proof. 1.45 air changes per hour at 50 pascals of vacuum. Off the chart and we're not even done yet.

Gerry tracks down and seals up air leaks in the thermal envelope. This is how we perform so well in our air leakage testing.

A Polar Foam technician sprays closed cell foam in the attic. This creates an almost airtight and highly efficient thermal envelope. Learn more at Polar Foam Insulation.

Steve planes out the top cord on one of the roof trusses for a perfect fit.

Bill chisels off a high spot in one of the roof trusses.

Steve checks the string line to assure proper planing of the roof trusses.

John Boy uses a chalk line to check alignment of the truss blocking.

Robbie and Robert plan the truss installation.

Slim checks the crown on the deck joists to make sure it's installed crown side up.

Chris installs stainless steel deck joist hangers. This is very important on the water front homes to prevent corrosion.

Nate insulates one of the second floor window headers.

You can see the fiberglass batt hanging out of the bottom of this header. We insulate our headers to reduce heat loss through the thermal envelope. We will use about 3 rolls of insulation for the headers on this job which adds quite a bit of energy efficiency to areas that are not normally insulated. Imagine the impact of removing 3 rolls of insulation from your home.

Steve guides a pre-assembled hip set into position on the second floor.

John applies to the floor trusses to ensure complete adhesion of the floor decking.

Robert builds an insulated header. You can see the fiberglass batt hanging out of the bottom of this header. We insulate our headers to reduce heat loss through the thermal envelope. We will use about 3 rolls of insulation for the headers on this job which adds quite a bit of energy efficiency to areas that are not normally insulated. Imagine the impact of removing 3 rolls of insulation from your home.

Brian, Mike, and Brian place and finish the concrete.