Gallery Of Homes: Kelly

A built-in entertainment center for the Kellys.

Gerry sets a column on the dining room built in buffet.

Gerry installs 5" crown molding in the master bedroom.

Chris and Robert embed glass fiber mesh into the brown coat to reinforce the front foam formed porch columns.

Mark installs the garage doors. The long horizontal bars strengthen the doors to 110 mph wind resistance.

Chris shapes the arch key over the front porch.

Robert applies finish to the garage door trim bands.

Robert brown coats the front porch archway.

Dennis sprays drywall texture on the ceiling in the living room.

Dennis mixes drywall mud in his high pressure spray rig.

Jeremy builds the mail box.

Jeremy lays up brick on the back porch.

Open cell foam is sprayed in the attic to create a high efficiency, air tight, thermal envelope.

The wild bunch? Robert, Joe, John, Nate, Brandon, Dave, Slim, Steve, and Jordan.

Nate lines the window jams with moisture resistant flashing tape.

Joe screws off the impact glass windows with stainless steel hex head screws. Laminated impact glass protects your home from hurricane damage, intrusion, and it's a lot quieter inside.

Josh installs flashing tape around the window flanges. This window will never leak.

Heads up gator boys! John tosses gatorade up to Robert.

Brandon and Roger cut and fit foam insulation in between the firring strip cavities to insulate the outside walls of the safe room.

John and Robert build the triple step front porch cornice.

Slim, Brian, and Nate install 50 mil peal and seal underlayment. This helps maintain the water tight integrity of the roof should any of the shingles be damaged during a hurricane.

Nice view of Ski Lake in Milton. They should have named it Ski Heaven. Kay's in it practically every day. Pretty soon her toes are going to start growing together.

Willie pours the roof on the safe room. Note the steel reinforcement bars. This safe room is engineered to withstand 250 mph winds and 100 mph misslie impacts. The house can completely collapse around the safe room and the occupants will be protected.

Concrete is poured into the hopper of a line pump, then it's pumped through a hose up to Willie who directs the concrete down into the walls and roof. This safe room is engineered to withstand 250 mph winds and 100 mph missile impacts. The house can completely collapse around the safe room and the occupants will be protected.

Laying up block in the safe room. In this case the safe room is also the master closet. Steel bars will be placed inside the block cells and then poured solid with concrete.

Joe is pretty happy about this pre insulated Tee. If you add up all the exterior tees, corners, and window headers that normally are not insulated in a code built home it amounts to about 2 full rolls of insulation on a 2000 sf home. Imagine removing 2 rolls of insulation from your walls and how that would affect your utility bill and comfort level of your home.

Joe uses a rub rock to smooth out the slab around the anchor bolts.

Willie operates the rotary trowell.

Snake trowells the slab.

Calvin finishes around the dowell rods that will anchor the safe room walls to the foundation.

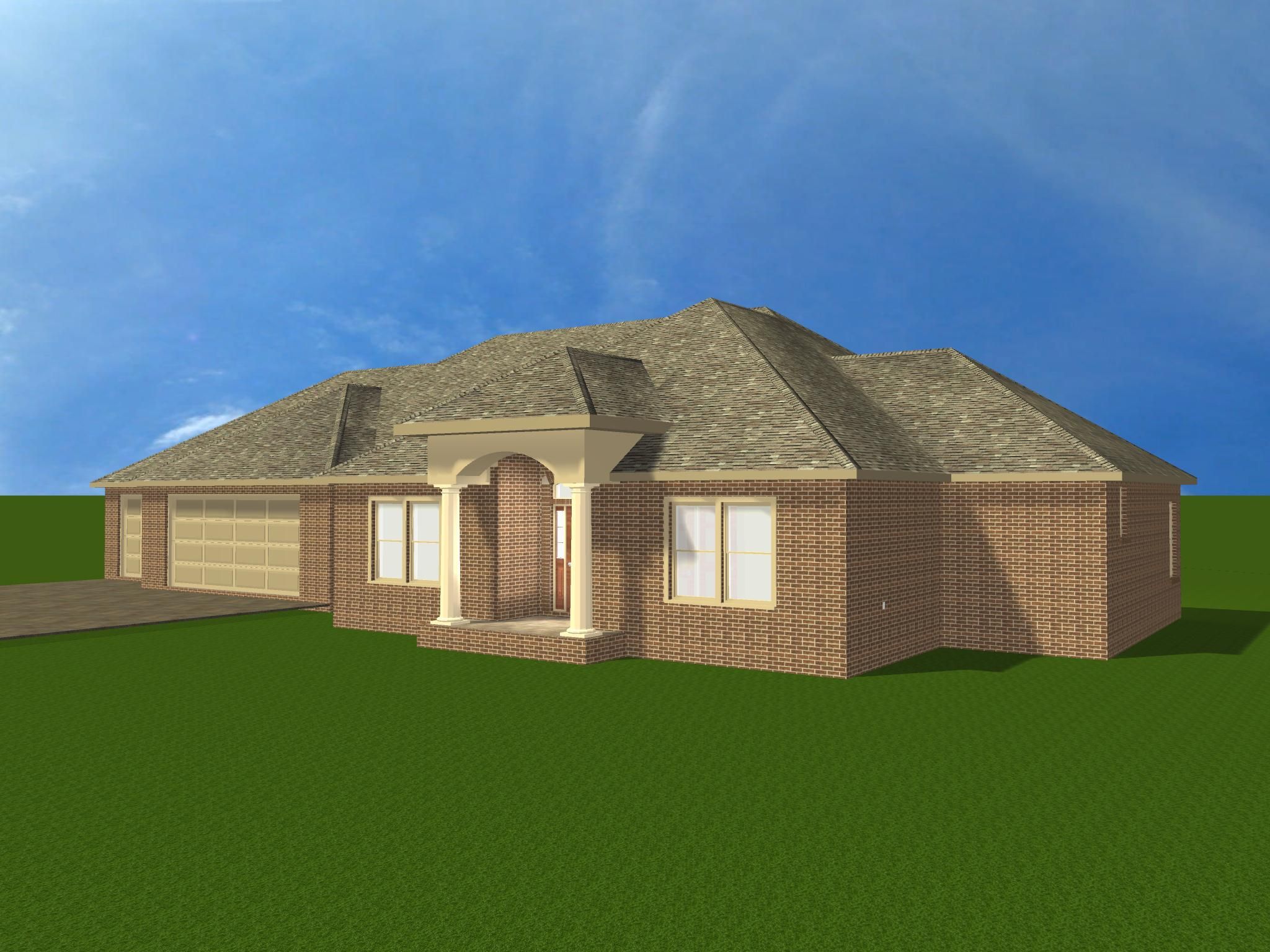

Front view

Left front view

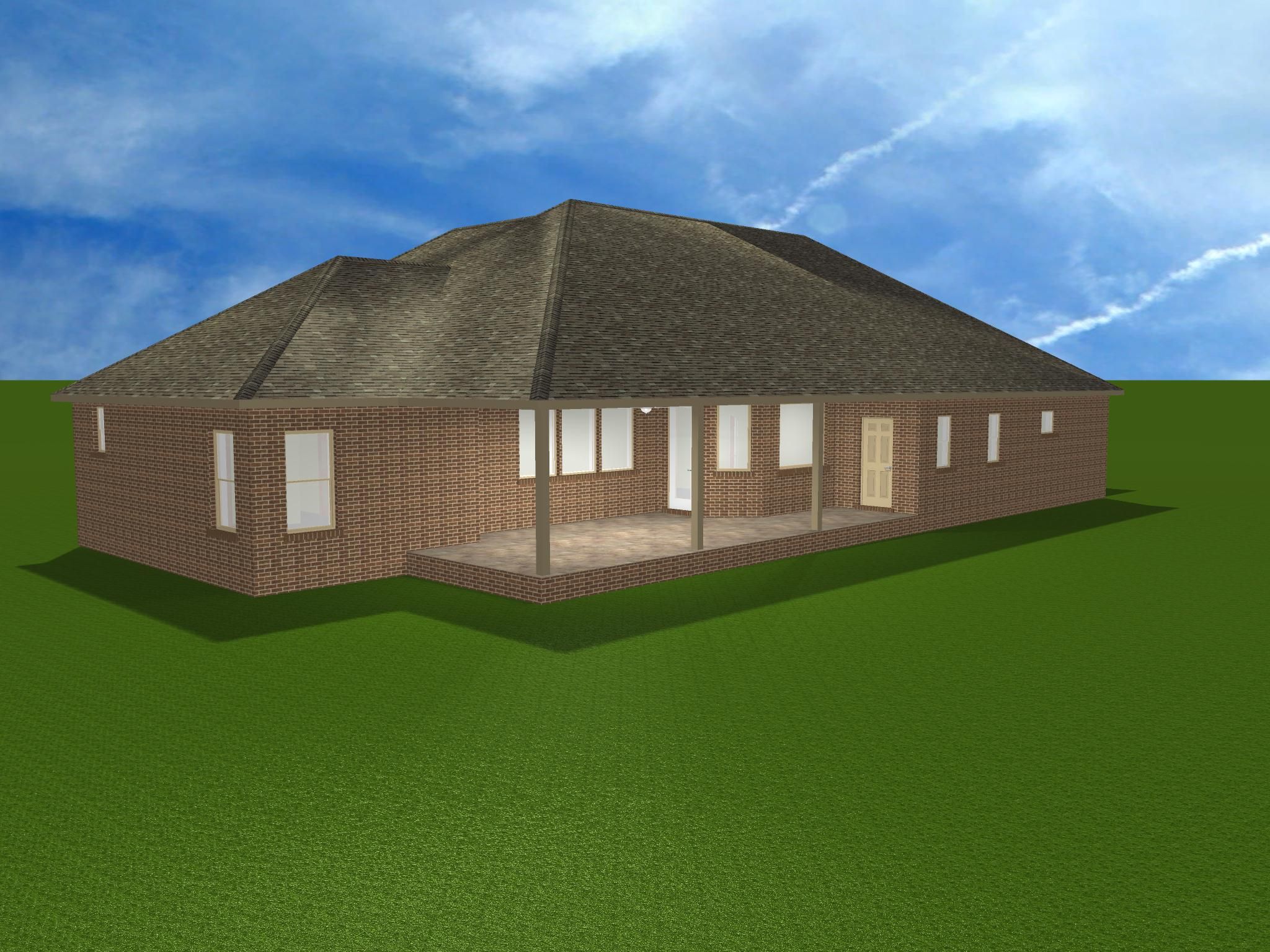

Left rear view

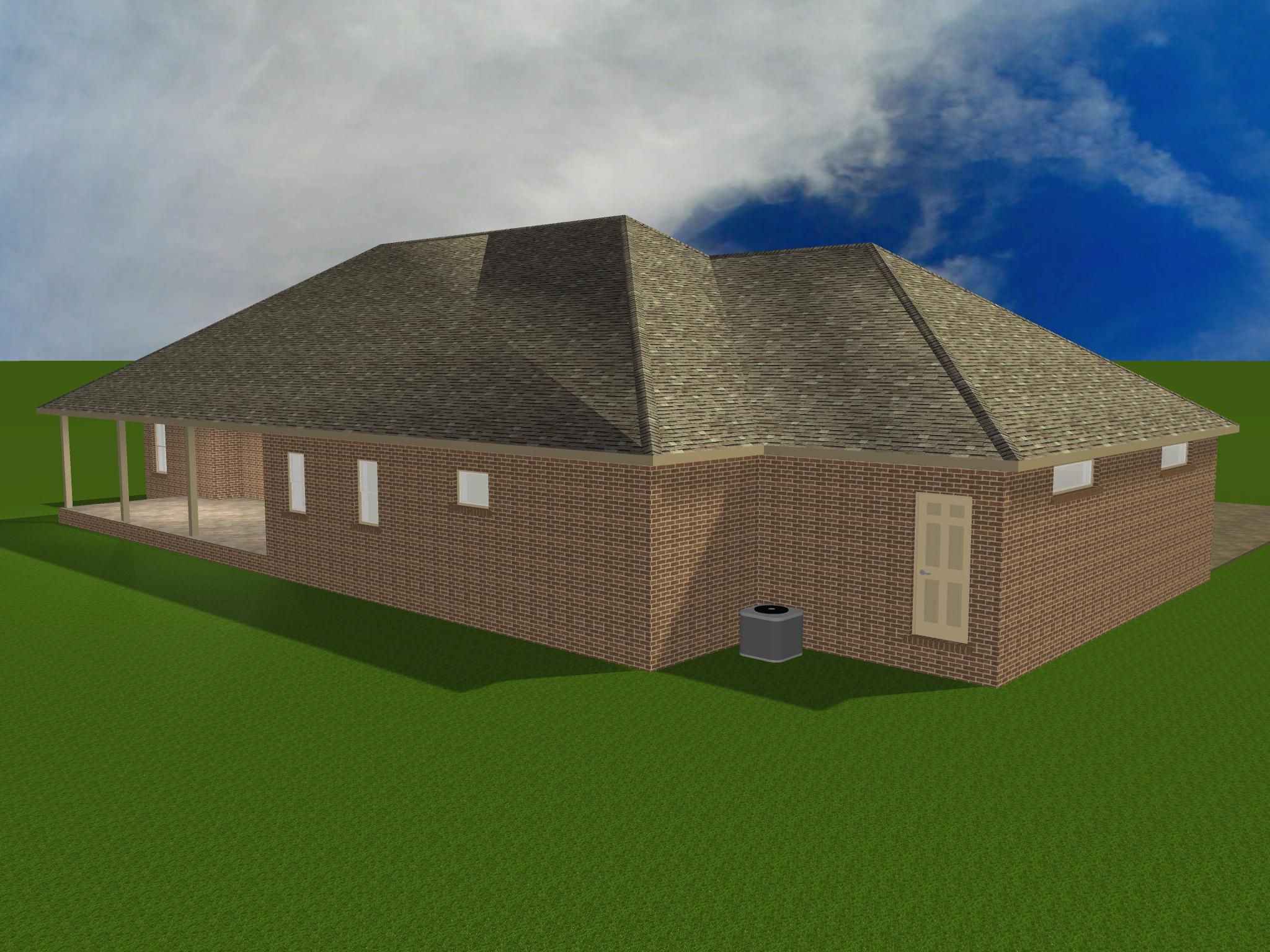

Right rear view

Right front view

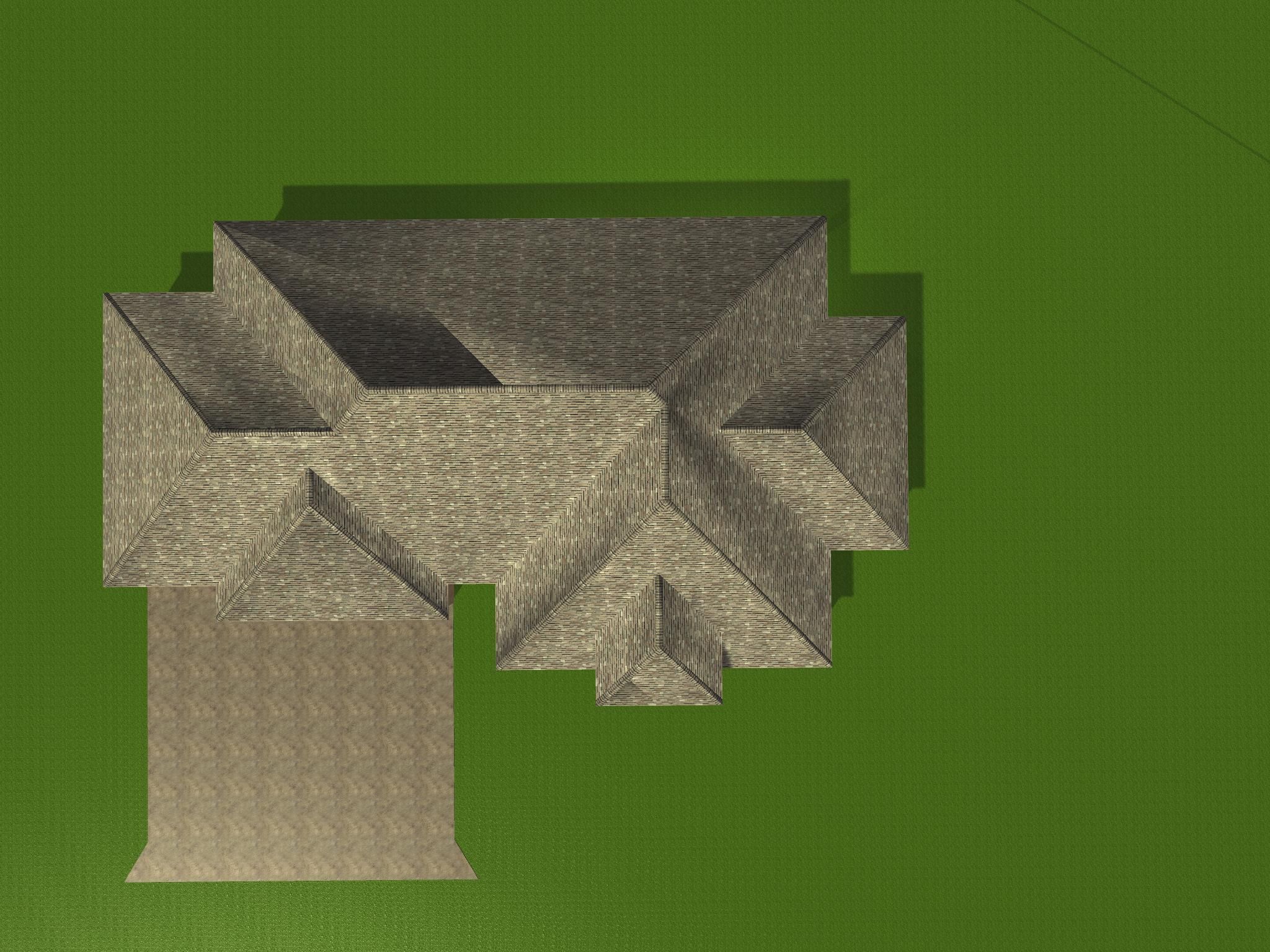

Top view