Gallery Of Homes: Haggett

We applied a beige 2 part epoxy coating with deco flakes to the garage floor. Epoxy coatings resist tire damage better than any other type of floor coating. You can see the central vac machine hanging on the wall.

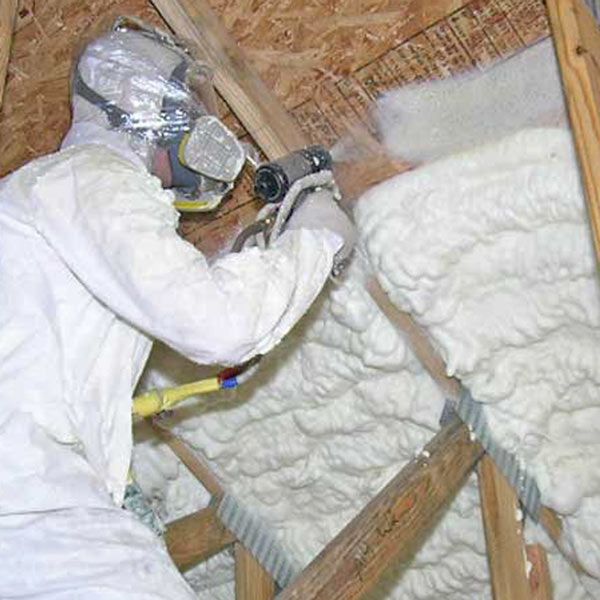

Willie with Coastal Insulation blows fiberglass insulation into the wall cavities.

This is the wall between the kitchen and the theater room which has special sound isolation features. The 2x4 studs are staggered along a 2x6 top and bottom plate so that no stud touches both sides of the wall. This substantially reduces acoustic bridging. Drywall has been hung on the theater side of the wall and now the netting is being installed on the kitchen side. Next step will be to blow insulation into the cavities. You can see one of the side channel speaker wires in the wall. The wire will be fished out of the wall when the speaker is mounted.

Maurice with Coastal Insulation installs sound batts in the interior study walls. The red marks show him which walls get sound batting. All interior bedroom, bathroom, game room, and study walls are sound batt insulated.

Here's how the theater room wall turned out.

This blown-in-batt product produces an R-23 wall. The 2x6 exterior wall studs are placed 24" instead of 16" apart allowing more insulation to be placed in the wall for better thermal performance. A 2x6 stud is R-8 compared to R-23 for the BIB insulation. You can fit 67% more insulation in this type of wall than a typical 2x4 wall framed 16" apart.

On the right you can see a ladder framed tee. Typically this intersection of 2 walls is framed with a solid stud on each side so you can't insulate behind it. By using horizontal ladder blocking to connect the walls you can insulate behind the intersection thus forming a complete and uninterrupted thermal envelope. The green dye is from the borate termite treating on the bottom 2 feet of the walls.

Thermoply lining goes behind the tub so insulation can be packed in behind the tub along the exterior walls. This area is typically not well insulated if at all.

Pouring the foundation footings

Tony laying up block.

Matt grading and compacting the foundation fill.

Pat with Florida Pest Control pretreating the slab.

Junior setting the steel in the interior load bearing footings.

Junior trimming the block.

We had to use a boom pump on this job. Concrete is dumped into a hopper on the back of the truck then pumped through a hose on the boom.

Junior cuts off a wild hair, a piece of rebar sticking out of the concrete. The slab has a wild hair.

Greg on the hose. Notice how his foot sinks down into the footings for the safe room. There are 30" wide footings with 3 #4 bars under the safe room to make sure the safe room is a completely independent structure capable of withstanding an entire collapse of the home should it receive a direct hit by a tornado.

Steve Haggett, the home owner, making himself useful pouring the garage.

OK, you're hired. But Arturo doesn't seem so sure about the new guy.

There weren't enough boots to go around so somebody had to work in their socks. As you can see, rank has its privileges.

Mission accomplished! CMSgt Haggett, fully qualified as a hose man on the Schwing 41 meter boom pump.

Screeding in the foreground. Gomez on the bull float in the back ground. Bull floating smooths the surface and pushes the agregate (rocks) down below the surface and allows the cement and water to rise to the surface where the water evaporates and leaves a higher concentration of cement to create a harder surface.

Greg on the rotary trowel.

Junior cutting joints into the slab to prevent uncontrolled shrinkage cracking.

Tony drilling holes into the safe room footings so steel dowel rods can be epoxied in to tie the safe room walls to the steel reinforced footings below. There will be 2 steel dowel rods in each block of the safe room walls, then concrete poured inside to tie the walls to the slab and footings below.

Building the safe room.

Greg lays up a corner of the safe room. Note the steel dowels in each cell. These 1/2" steel bars are epoxied into the slab. When the block is poured solid with concrete they tie the room to the slab and it's reinforced footings below.

Will work for ice cream.

Tatiana cleaning the mud mixer. No hate mail please. She only worked 6 hours that day.

Gomez setting the top course on the safe room.

Gomez finishing the safe room roof. The safe room is engineered to withstand 250 mph winds and 100 mph missile impacts.

Ernie installing the sill plate gasket which makes the walls air tight at the bottom. Wayne nailing the bottom plate to the studs.

Wayne, Ernie, and Terry raising the garage wall. This wall is common to the living area so it's a 2x6 wall to allow for more insulation in that wall.

Deer in the hood, dining in the neighbors garden on Cove St. These same 3 deer walked right by the framers later in the day on the return leg of their trip to the golf course lots.

Wayne and Ernie installing the wall sheathing on the garage. Note the horizontal blocking at the joints which strengthens the wall framing and ties the 2 rows of sheathing together. Running the 4x8 panels horizontally results in a stronger wall.

Terry checking for straight, level, and plumb. Note the open corner. This advanced framing technique allows the corner to be insulated unlike conventional framing where the corner is closed in and can't be insulated.

Craning in the trusses.

Ernie holds the tag line while Bruce guides the truss into place.

Terry tosses a positioning block up to Wayne. Good catch!

Kenny and Wayne wrestle the truss into proper position.

Bruce and Wayne nail off positioning blocks to hold the truss steady until decking.

Bruce toenails the truss over the front door. These are temporary fastening. Later a hurricane clip will be installed for a permanent and stronger connection.

Wayne nails off the 2x6 facia board. It's important to set the facia level and plane with the trusses prior to installing the decking.

Wayne and Chris installing decking on the back porch.

Chris & Wayne checking alignment of the decking at the valley.

Peal & seal sub roof in place. This is a water tight 50 mil secondary roofing membrane which will protect the home in the event of a lost or damaged shingle during a hurricane.

Installing metal lath for the stucco on the front porch.

Domingo troweling on the stucco, Miguel combing in the groves to make this the scratch coat. Brown coat comes next followed by finish color coat.

Francisco and Santana hauling mud, human 4x4 style.

Mark applies roofing cement to the chimney flashing so the shingles will adhere properly at this vulnerable spot.

Mark lacing the valley. Each shingle gets 6 nails but nails are kept 6-12" away from the valleys to prevent leaking.

Tommy nailing off starter shingles at the edge. Note the bed of roofing cement which adheres the first shingle to the eve metal which prevents wind from peeling up the roof.

Haggett residence

Steven and Lisa Haggett are both USAF chief master sergeants soon to be retiring this year. I designed their 3274 SF retirement home for construction in Hidden Creek Estates while they were still on duty at the Pentagon. This home has storm-tuff features, a safe room, and a home theater. They'll both be working in civil service jobs at Hurlbert field in mission critical jobs so the safe room ensures that they won't have to evacuate and will be available for duty during hurricane threats, not to mention totally safe from bodily harm.

This home is VA financed.

"I'm a control freak and I was pretty nervous at the beginning, having my retirement home built while I was still on active duty, out of town, and sometimes out of the country. Les handled everything and went the extra mile to make sure I got what I wanted and then some. Les and his wife, Tammy, recommended fixtures, tile, granite, stone, and misc selections for us which we liked better than what we would have picked out on our own. Les sent pictures so we could see what was being recommended. Our house turned out absolutely fantastic! Like I said, I'm a control freak and this whole process far and away exceeded my expectations. We were in the loop with pictures and communications the whole time. I've heard all the horror stories about having a home built and non of those came true for me. This is our last house and we can't wait to start enjoying the rest of our lives in it."

~ Steve Haggett